Category: Disposable PPE

Category: Disposable PPE

Disposable gloves are personal protective equipment (PPE) commonly made from single-use plastics and other disposable materials. Nitrile gloves are a typical product in this category, made of synthetic rubber and typically packaged in a cardboard box. Other types of disposable PPE include face shields and gowns. Nitrile gloves are classified as general waste or regulated medical waste depending on use case. The routine, high-volume use of nitrile gloves in health care settings can result in substantial emissions.

This brief summarizes a carbon footprinting study of a nitrile glove incinerated after its one time use in the United Kingdom, to identify typical hotspots and potential interventions to decrease product emissions.

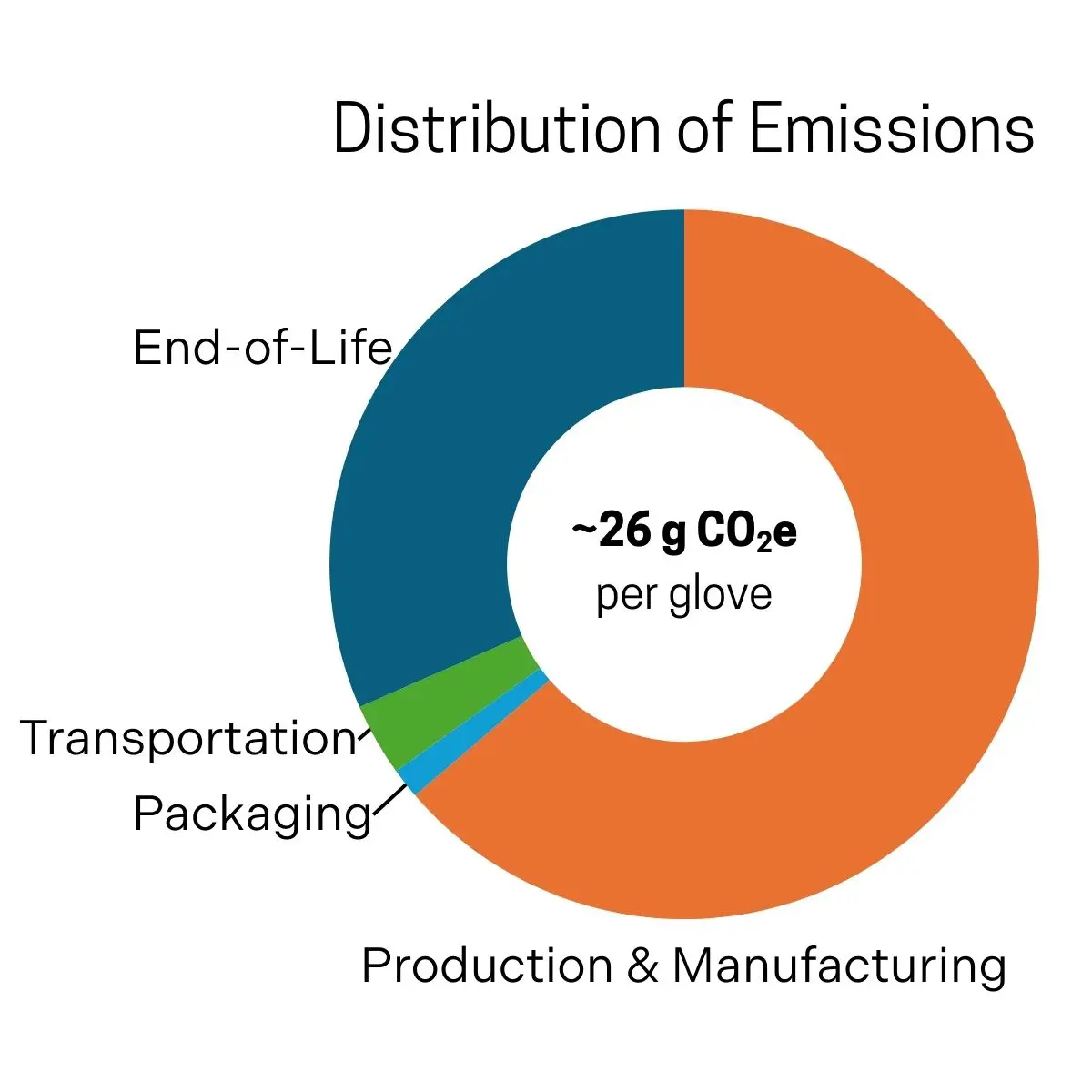

Carbon Emissions Across Life Cycle

The major hotspot for nitrile gloves is production and manufacturing, specifically of synthetic rubber. The majority of those emissions are from energy use and raw material production. The gloves are assumed to be incinerated at end-of-life, accounting for one-third of total product emissions. Packaging and transportation make small contributions, and the use of the product has no associated emissions.

Focusing on Carbon Hotspots

The most impactful interventions focus on reducing overuse and improving manufacturing of nitrile gloves. Based on these results, specific suggestions for different stakeholders include:

1. Reduce unnecessary usage:

⛨ Provide evidence-based training around hand hygiene and appropriate glove use, including highlighting situations when using gloves is not necessary.

⛑ Improve guidelines around sterile and non-sterile glove use.

2. Reduce emissions associated with materials and manufacturing:

⚙ Use on-site or procured renewable electricity for manufacturing operations

⚙ Redesign product where possible to reduce overall material requirements while maintaining its intended use.

$ Consider less carbon intense materials, such as latex, when appropriate.

3. Improve glove design and circularity:

$ Select higher-quality, durable designs to minimize breakage and avoid layering of gloves.

☑ Participate in glove recycling programs.

Audience Key: ⛨ Clinicians | ☑ Administration | ⚙ Manufacturers | $ Procurement | ⛑ Regulators

Reference: Rizan et al. 2021. “Environmental Impact of Personal Protective Equipment Distributed for Use by Health and Social Care Services in England in the First Six Months of the COVID-19 Pandemic.” Journal of the Royal Society of Medicine 114, no. 5: 250–63.

Related Products